Where Is Manufacturing Headed? Three Industry Trends to Watch

Manufacturers are leaning into digital transformation more than ever. Nearly 30% of worldwide digital transformation spending by 2026 is forecast to come from the discrete and process manufacturing industries.1 Those investments are paying off. According to the Department of Defense, U.S. manufacturing is a major engine of innovation in the U.S., responsible for 55% of all patents and 70% of all research and development spending.2 That’s impressive. Clearly, the fourth industrial revolution (Industry 4.0) is underway.

Industry 4.0 is all about using data to increase efficiency, optimize maintenance, satisfy customers and quickly capture ROI. To accomplish these goals, manufacturing businesses look to new technologies and partnerships. Priorities include rapid data collection, big data analysis and secure, low-latency interconnection.

As more manufacturing companies adopt a hybrid IT infrastructure, they’re choosing a colocation data center that offers cloud connections and networks offering access to an ecosystem of current and potential partners. Decision-makers also are evaluating industry trends to help them prepare for the future.

Manufacturing Industry Trends to Watch

What is becoming clear is that digital transformation happens in stages and there is no end-state. Decision-makers are weighing business goals against the large number of technology investment opportunities. The tricky part is balancing what’s needed today with what appears to make sense for the future. Industry trends show that edge computing, smart manufacturing and cloud adoption will stand the test of time.

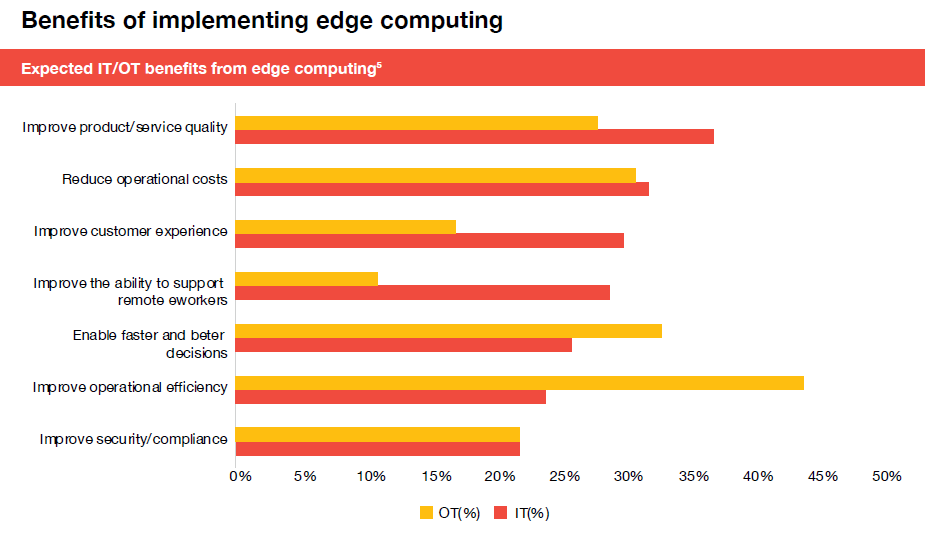

1. Edge Computing. All the connected devices that support manufacturing at the edge allow you to collect and analyze data close to its source. Process decisions can be made faster because the data doesn’t have to travel to and from a typical corporate data center. Speed counts in product design, maintenance, quality control, supply chain logistics and almost every other aspect of operations.

2. Smart Manufacturing. Smart manufacturing is a national priority in the U.S.4 Smart factories, the production arm of smart manufacturing, are gaining ground and improving both physical and virtual processes. Sensors are getting smarter, robots are capable of taking on more tasks and digital twins of factory facilities enable test drives prior to rolling out a new line. Keep in mind: 5G, a fundamental component of Industry 4.0, continues to expand. As you enhance wireless networks, be sure to update your cybersecurity practices to address any potential new vulnerabilities.

97% of participants reported that they are using or plan to use smart manufacturing over the next 1-2 years.5

3. Cloud Adoption. Top reasons for adopting cloud are to improve profitability and enable growth. How? Through centralized, data-driven operations and software as a service (SaaS) solutions. SaaS can be advantageous in many areas: data analysis, collaboration, real-time monitoring/reporting, supply chains, production planning, inventory management, customer relationship management – the list goes on.

Over the next 12 months, 44% of respondents plan to increase investment in cloud technology, applications or infrastructure.6

Hybrid IT Accelerates Business Outcomes

Hybrid IT is the infrastructure of the future. When you work with CoreSite experts, expect a collaborative approach that helps you prepare your business for the future. We’ll discuss trends, solve technical challenges and accelerate your digital transformation plans – in part through our ecosystem of digital platform providers, managed service providers, systems integrators and other companies.

Our customized data center deployment solutions and network-dense, high-performance data centers offer an ideal environment for hybrid IT infrastructures helping manufacturing enterprises scale dynamically, lower total cost of operation and reach new markets through interconnection.

We’ve recently released a white paper Manufacturing Industry Trends: Going Digital with Interconnection, Industry 4.0 and Hybrid IT. I’ve touched on a few key points from that discussion and am confident that you will find more insights proving valuable by downloading and reading it today. It’s offered ungated as part of our manufacturing industry content hub.